Understanding and Optimizing Polyester POY Yarns: A Comprehensive Guide

Update:06-11-2025

Abstract:Introduction

What are POLYESTER POY YARNS?

The term POLYESTER POY YARNS refers to polyester filament yarns that have be...

Introduction

What are POLYESTER POY YARNS?

- The term POLYESTER POY YARNS refers to polyester filament yarns that have been only partially oriented after melt spinning, forming a semi‑finished yarn suitable for further processing.

- They serve as the feedstock for producing textured yarns such as DTY (draw textured yarn), and are widely used across upholstery, carpet, blanket and performance fabric applications.

Why this guide matters for textile manufacturers and buyers

- Choosing the right POY yarn impacts final fabric performance — strength, dyeability, shrinkage and appearance.

- By understanding the nuances of POY types and manufacturing, specifiers can make more informed decisions when selecting yarns like "polyester poy yarns for upholstery fabric" or "dope‑dyed polyester poy yarns 30D to 600D".

- With sustainability an increasing priority, knowledge of options like "sustainable recycled polyester poy yarns manufacturing" becomes a competitive advantage.

Section 1 – Key Specifications and Types of Polyester POY Yarns

Denier/filament range (e.g. 30D to 600D) and what that means

- Many manufacturers offer POY in ranges from 30D up to 600D, enabling versatility across applications from fine knit fabrics to heavy home‑textile fabrics.

- A lower denier (e.g. 30D) typically yields finer yarns with lighter weight fabrics; a higher denier (e.g. 600D) is suitable for heavier duty uses like upholstery or carpet backing.

Colour options and processing: raw white vs dope‑dyed

- Standard POY often comes in raw white; however producers also supply dope‑dyed POY where colour pigment is added during melt spinning, enabling consistent colour throughout the filament.

- When choosing products such as "dope‑dyed polyester poy yarns 30D to 600D", buyers gain benefits in colour fastness and production efficiency.

Lustre types: semi‑dull vs bright

- The two common luster types for POY are semi‑dull (matte finish) and bright (shiny finish); each lends different aesthetics and functional attributes to the final fabric.

- For example, a matte look is often preferred for upholstery and home‑textile fabrics, whereas a bright luster may be chosen for fashion fabrics.

Comparison table: Semi‑dull vs Bright POY

| Specification |

Semi‑Dull POY |

Bright POY |

| Lustre / Appearance |

Matte, low shine |

High shine, glossy |

| Typical Applications |

Upholstery, carpets, home textiles |

Knits, fashion, decorative fabrics |

| Cost / Processing |

Often lower cost, simpler finish |

Often higher cost due to optics, finishing |

Section 2 – Application Areas for Polyester POY Yarns

Upholstery fabrics

- When selecting for upholstery fabric applications, specifiers often look for POY yarns with consistent filament quality, colour stability, and durability — e.g., "polyester poy yarns for upholstery fabric".

- Higher deniers and semi‑dull luster are commonly used to resist abrasion and maintain visual appeal in heavy‑use furniture environments.

Blankets, carpets and home textiles

- Home‑textile uses such as blankets and carpets demand POY yarns that provide bulk, colour consistency and resilience — thus the relevance of selecting correctly: "how to choose polyester poy yarns for carpet and blanket".

- For carpets, higher deniers and textured processing (via downstream DTY) are typical to deliver thick fabrics and good performance.

Industrial and technical fabrics

- Beyond home textiles, POY yarns also feed industrial fabrics (e.g., geotextiles, automotive textiles) where controlled shrinkage, high strength and dimensional stability are key.

Section 3 – Selection Criteria & Manufacturing Considerations

What to check when choosing POY – strength, elongation, shrinkage, dyeability

- Important specification parameters include tenacity (strength), elongation at break, shrinkage after draw/texturising and dye uptake.

- For example, a POY used for textured yarn feed must have good uniformity and appropriate shrinkage profile so that downstream DTY quality is stable.

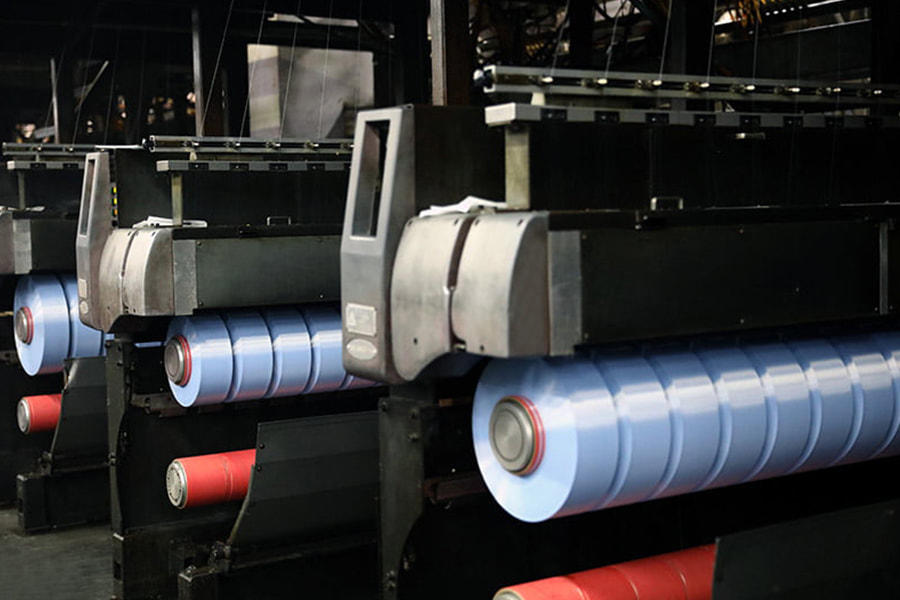

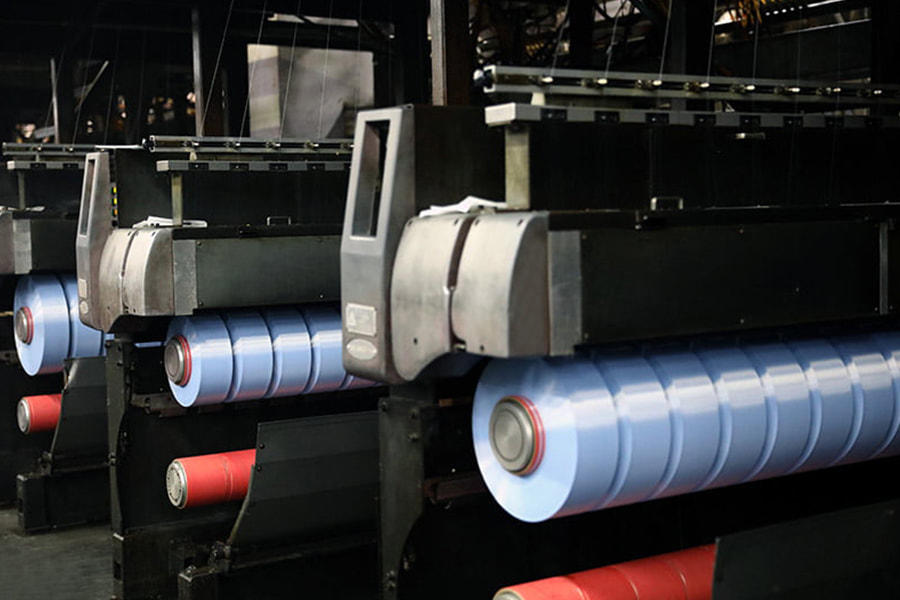

Manufacturing process highlights – melt spinning, partial orientation

- The process begins with molten polyester (from PTA & MEG) being extruded, quenched, and partially drawn to produce POY — the "partial orientation" distinguishes it from FDY (fully drawn yarn).

- Understanding this helps buyers appreciate why POY is more cost‑effective than FDY for many applications, and how its characteristics differ.

Sustainability and recycled POY manufacturing

- As textile supply‑chains seek lower carbon footprints, the option of "sustainable recycled polyester poy yarns manufacturing" becomes important — recycled PET feedstocks, certification schemes and associated value‑adds matter.

- Suppliers that provide this sustainability dimension build stronger long‑term partnerships with fabric manufacturers and brands.

Section 4 – Why Choose Our Company's POY Yarns

Company overview: Zhejiang Hengyuan Chemical Fiber Group Co., Ltd.

- Established in 2006, located in YaQian Town, Xiaoshan, Hangzhou — one of the centres of the polyester yarn industry in China.

- Covering 120,000 m² land area and 150,000 m² building area; group covers six branch companies, total assets USD 150 million, and staff of ~1000.

Production capacity and product range

- The group includes two polyester yarn companies and two fabric textile companies, with capacity of 150,000 tons of polyester yarn and 50 million m/yr of various pure and T/R elastic fabrics.

- Specialising in polyester yarn FDY, POY, DTY, from 30D to 600D, both raw‑white and dope‑dyed colours, widely used in fabrics such as upholstery cloth, blanket, carpet.

Quality, certifications and sustainability commitment

- Our consistent and stable quality, growing sales, and social donation record earned us honours such as "TOP 100 INDUSTRY COMPANY IN XIAOSHAN", "GREEN ENVIRONMENTAL AND TRUST COMPANY OF CHINA", "HIGH TECH OF HANGZHOU".

- When you choose our POLYESTER POY YARNS, you benefit from reliable supply, broad specification range and strong sustainability credentials.

Frequently Asked Questions (FAQ)

1. What does "POY" stand for and how does it differ from other polyester yarn types?

- POY stands for Partially Oriented Yarn. It is less drawn than FDY (Fully Drawn Yarn) and serves as feed‑yarn for textured or drawn yarns.

2. How do I choose the right denier when selecting polyester POY yarns?

- Consider fabric application: finer deniers (e.g., 30D–100D) are suitable for light textiles; heavy applications like carpet or upholstery may require 300D–600D range. Also check downstream processing and performance specifications.

3. What is the benefit of dope‑dyed polyester POY compared with raw‑white yarns?

- Dope‑dyed POY has colour pigment introduced during melt spinning, offering uniform and stable colour throughout the filament and improved dye fastness. It simplifies downstream processing and improves consistency.

4. When should I select semi‑dull versus bright POY yarns?

- If the end‑fabric needs a matte appearance and less glare (e.g., upholstery, carpets), semi‑dull POY may be preferable. For fashion fabrics or decorative uses where shine is desired, bright POY is better. The comparison table above helps decide.

5. How important is sustainability in POY manufacturing and what should I ask the supplier?

- Sustainability is increasingly important: ask for recycled PET‑feedstock, certifications, energy‑efficient processes and transparent supply chain. Terms like "sustainable recycled polyester poy yarns manufacturing" reflect this trend.

Conclusion

Key take‑aways

- The right selection of POLYESTER POY YARNS influences fabric performance, aesthetics and cost effectiveness.

- Understanding specifications (30D‑600D), finish types (semi‑dull vs bright), dye/colour options (raw‑white vs dope‑dyed) and applications (upholstery, carpets, home textiles) puts buyers ahead.

- Partnering with a manufacturer like ours ensures specification breadth, reliable capacity and strong sustainability credentials.

Next steps for buyers and specifiers

- Define your end‑use and required fabric performance.

- Match yarn specification (denier/filament, luster, colour) to that end‑use.

- Engage with your supplier early on sustainability and supply‑chain transparency.